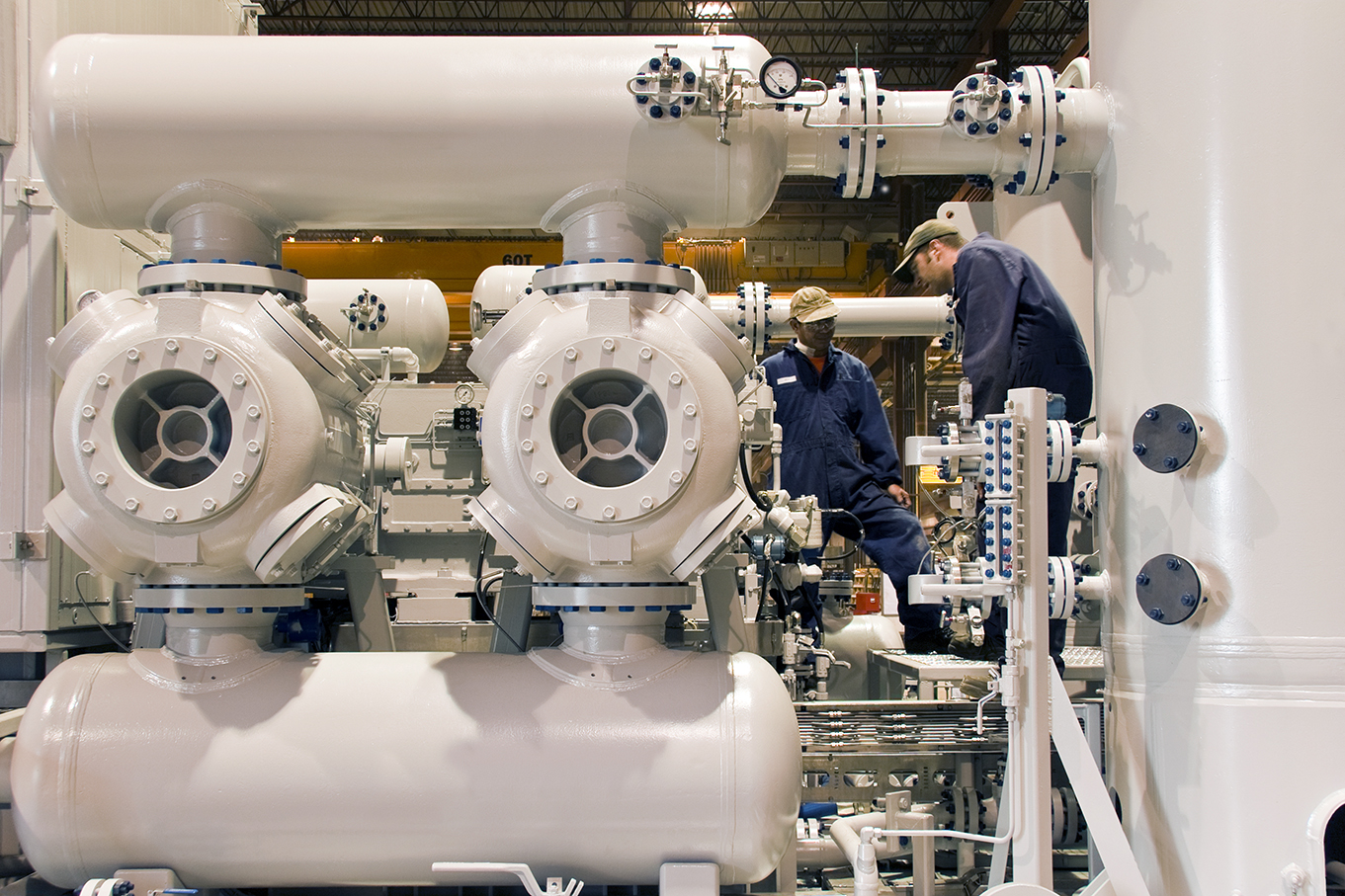

Following with the series of articles on multi-stage compressors, PCHE (Printed Circuit Heat Exchangers) heat exchangers represent a cutting-edge solution for interstage cooling, capable of managing complex flows in a compact design. Their multi-stream structure allows indeed for the integration of multiple heat flows in a single device, reducing space and complexity.

Critical advantages of PCHEs:

1. High thermal efficiency:

◦ Microstructured channels that maximize heat transfer.

◦ Reduction of energy losses.

2. Compactness:

◦ Extremely compact design, ideal for systems with limited space.

3. Resistance to extreme conditions:

◦ Designed to handle high pressures and temperatures, making them perfect for applications with hydrogen and other technical gases.

4. Versatility:

◦ Possibility of integrating multiple heat flows in a single device, reducing the number of equipment required.

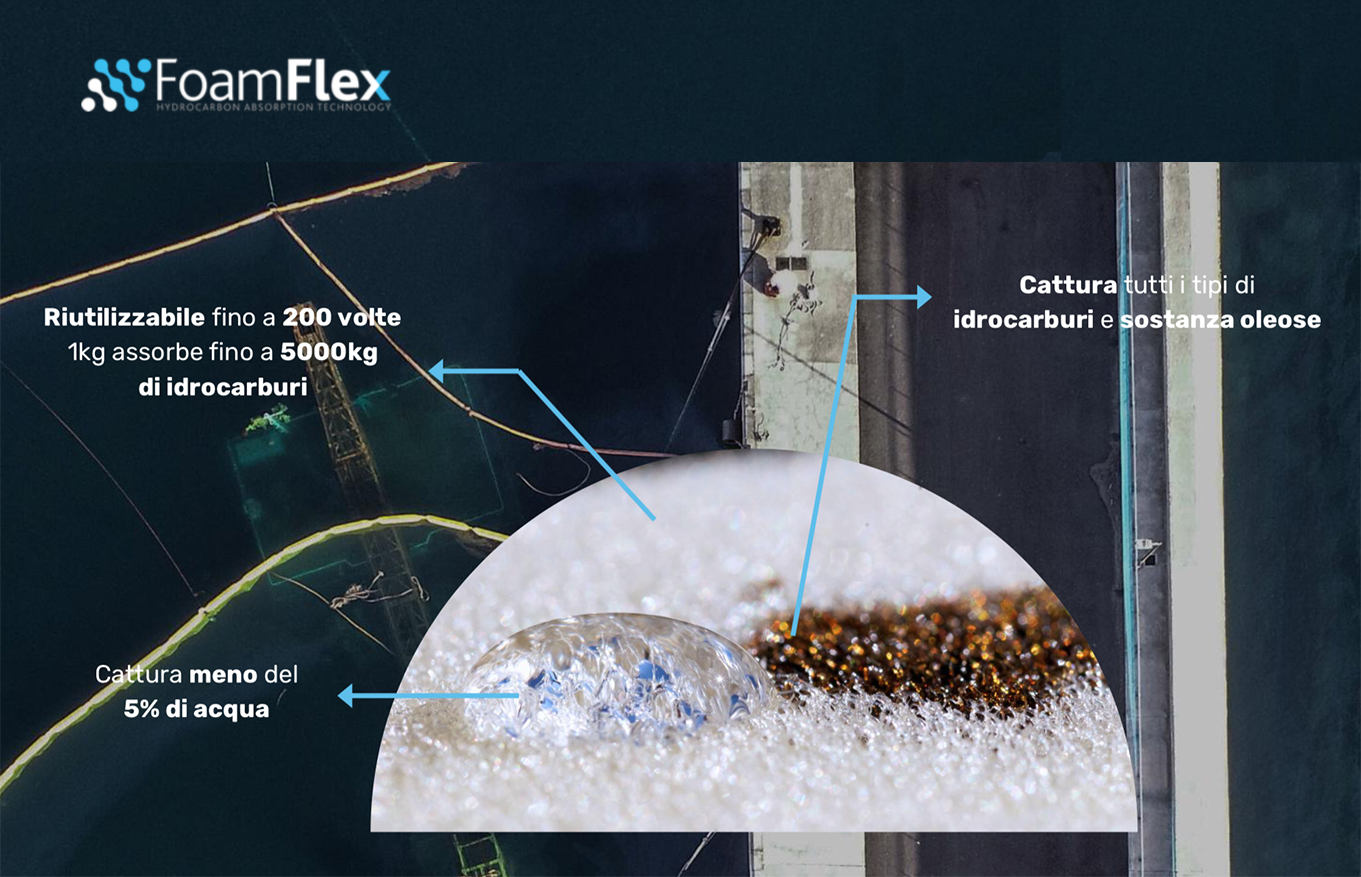

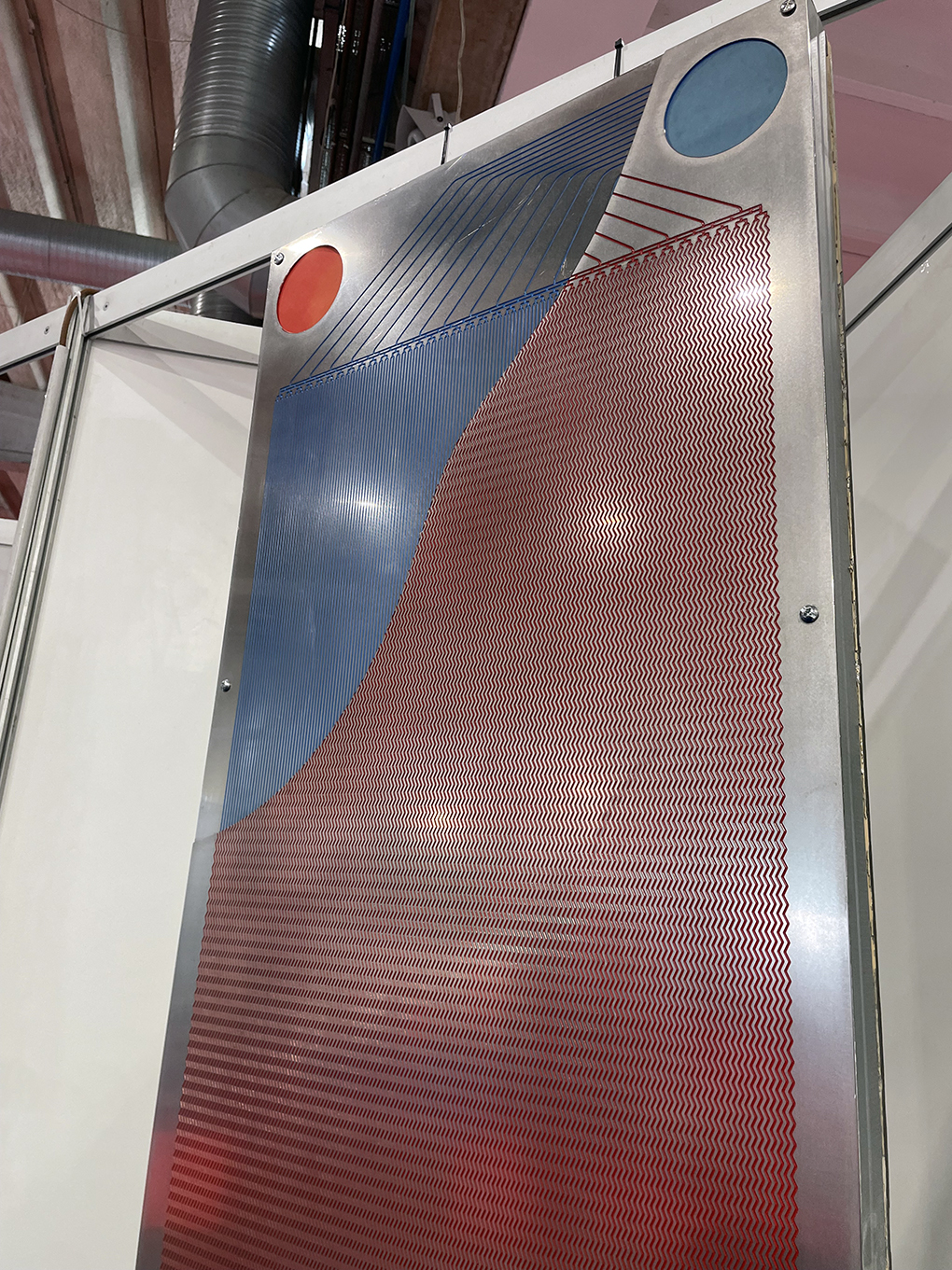

Microchannels pattern in the plates of PCHE heat exchangers

Disadvantages:

• High initial cost:

◦ PCHEs require a higher initial investment compared to traditional solutions.

• Clean or filtered fluids:

◦ Cleaning of microstructured channels may require specific techniques, so it is preferable to have filtered or otherwise clean fluids

Why then choose PCHEs? Despite the disadvantages, PCHE exchangers represent a strategic choice for critical applications where efficiency, compactness and resistance are essential. In particular, in the hydrogen sector, PCHEs offer a competitive advantage in terms of performance and sustainability, becoming a key technology for the energy transition.