We often discuss about heat exchangers, thermal energy recovery, working fluids, power generation and industrial processes in our Tempcoblog, expecting that many terms and concepts are commonly renowned for those who stop by and read our articles.

Going back to basics is then a good thing, reflecting on some essential concept, questioning and going in depth with something we often consider too much to go without saying. That being said both for first readers of our Tempco Blog on thermal energy solutions and for more frequent and returning readers of our pages.

First, let’s start focusing on what is a Heat Exchanger: it’s a machinery employed to remove and transfer thermal energy, without producing it nor requiring any further primary energy consumption. Heat exchangers exist in a wide range of types and sizes, plate heat exchangers and shell and tube heat exchangers, engineered using conductive metals able to transfer heat between two fluids, flowing in contact with the opposite metallic surfaces, also avoiding their mixing.

Small heat exchangers or bigger ones are built and engineered in order to satisfy a wide range of needs in industrial processes, in any kind of sector and application field. According to working conditions and the kind of fluids employed, several solutions are possible, choosing different materials, for example providing resistance to corrosive fluids, in case of heat exchangers for marine applications with sea water, or also fluids employed in chemical industry, oil & gas, but also in food & beverages and pharma.

Heat transfer is then a physical process that happens between two fluids, divided by the metallic surfaces of the heat exchanger, and the efficiency of this process is in direct proportion with some characteristics of the two fluids involved: density, specific heat, thermal conductivity and dynamic viscosity.

Density – also volumetric mass density, is the mass of a substance, expressed in kg, contained in a volume of 1m cubic

Specific Heat – is the amount of heat needed to increase the temperature of a mass of 1 kg of a fluid by 1°C

Thermal Conductivity – expresses the attitude of a fluid on transferring heat, and is obtained as a ratio between heat flow and the temperature variation caused by the heat flow itself

Dynamic Viscosity – represents fluid’s resistance to flow

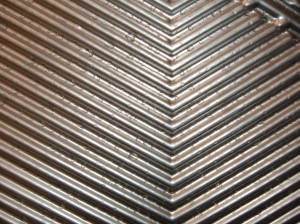

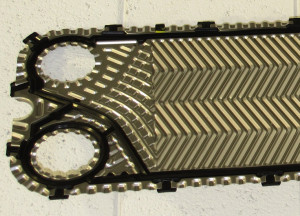

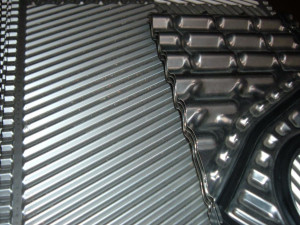

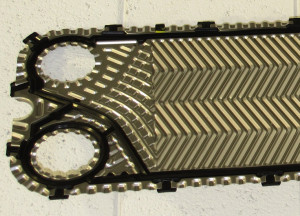

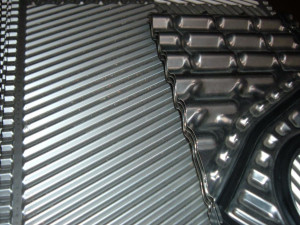

Referring to this last parameter, Tempco designs and realizes plates for heat exchangers with special patterns, intended to better allow and increase turbulence and speed flowing in fluids: indeed, higher the fluid’s flow speed, greater will be the heat transfer and efficiency of the heat exchanger.

For those who are interested in further informations on Thermal Energy, thermal machines, heat exchangers, evaporative towers, chillers, free coolers and thermoregulating units and their applications, you can read more on our Tempco Manual Thermal Energy and industrial processes – available here as e-book. http://bit.ly/1blm2iw