Sometimes I think it is useful to remember that the options to use plate heat exchangers are too great and allow the use in many different applications …

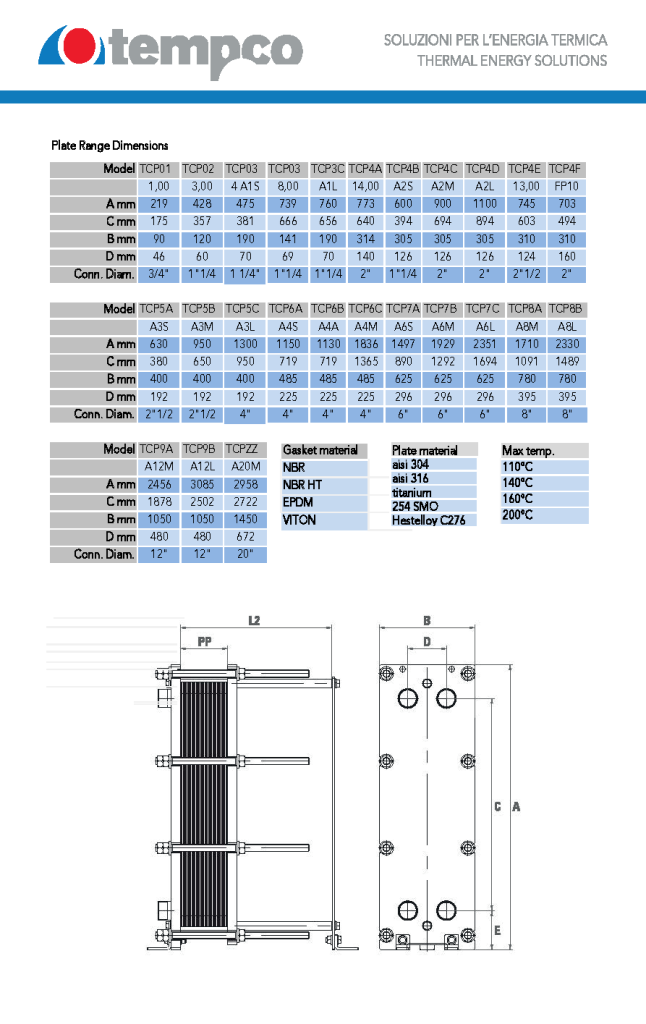

Tempco T PLATE P plate heat exchangers are complete of a support frame in painted carbon steel or stainless steel (for food and diary or pharma applications) and a plate pack with clip gaskets. There are different thermal lenghts, pressing depth and chevron angle.

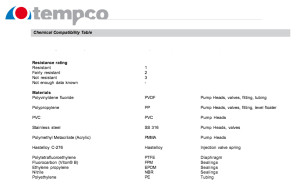

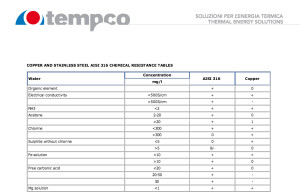

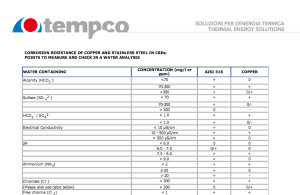

Standard plates materials

AISI 304, AISI 316, TITANIO, TITANIO/PALLADIO, 254SMO, HASTELLOY C276, INCONEL, MONEL

Standard gasketed material

- NITRIL

- NITRIL PEROXIDE

- EPDM

- EPDM PEROXIDE

- FPM

- PTFE

Gaskets type

LOCK SYSTEM GLUELESS (clip)

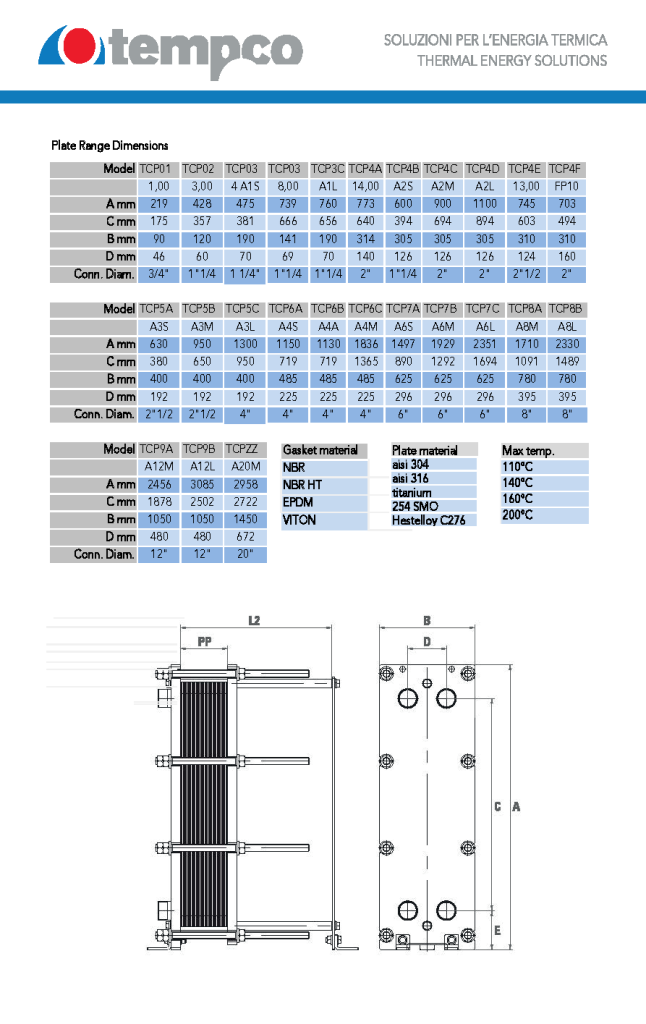

STANDARD PLATES RANGE

Connections from DN25 up to DN500 Standard connections:

threaded external or internal UNI and/or BSP, flanged UNI, ANSI, SAE TRICLAMP, for food and diary or pharmaceutical applications

Pressure range from PN6 up to PN25, full vacuum.

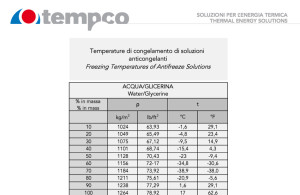

Temperature range from -50°C up to +200°C.

FRAMES

Painted carbon steel

Epoxy painting system for marine or aggressive environment

Acid proof painting

Teflon based painting

Special paniting system per food anvironment

Stainless steel multipass for diary applications

Pasteurizer multisection frames

Twin unit

BOLTS

Galvanized carbon steel

Stainless steel sor food and diary executions

SPECIAL EXECUTIONS

Electropolished plates for pharmaceutical applications

Double wall execution, for safe application on pharme, food and diary processes. DW application is a must where the 2 fluids can’t mixed themselves.