Lately we have made some particular heat exchangers.

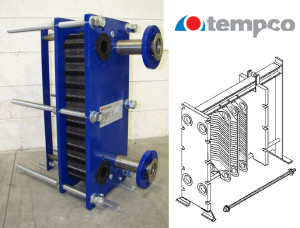

This is an application in the chemical, for temperature control of small laboratory reactors. Usually for these applications we use plate heat exchangers…but in this case because of some special needs we design a special tube bundle solutions.

Indeed the customer had need to pass the process fluid inside the heat exchanger, which for corrosion resistance implications, must necessarily be made of titanium. At the same time due to chemical resistance we dont find suitable gaskets. The size of the heat exchanger are so small that an “all welded” would be extremely expensive, so we made small shell and tube titanium exchangers.

For the cooling section, it has moderately cold water, and wanting to achieve a similar temperature level in the reactor jacket, we have realized a heat exchanger with very particular tube bundle, which allows to obtain the required temperatures, despite the capacity in very small dimensions.