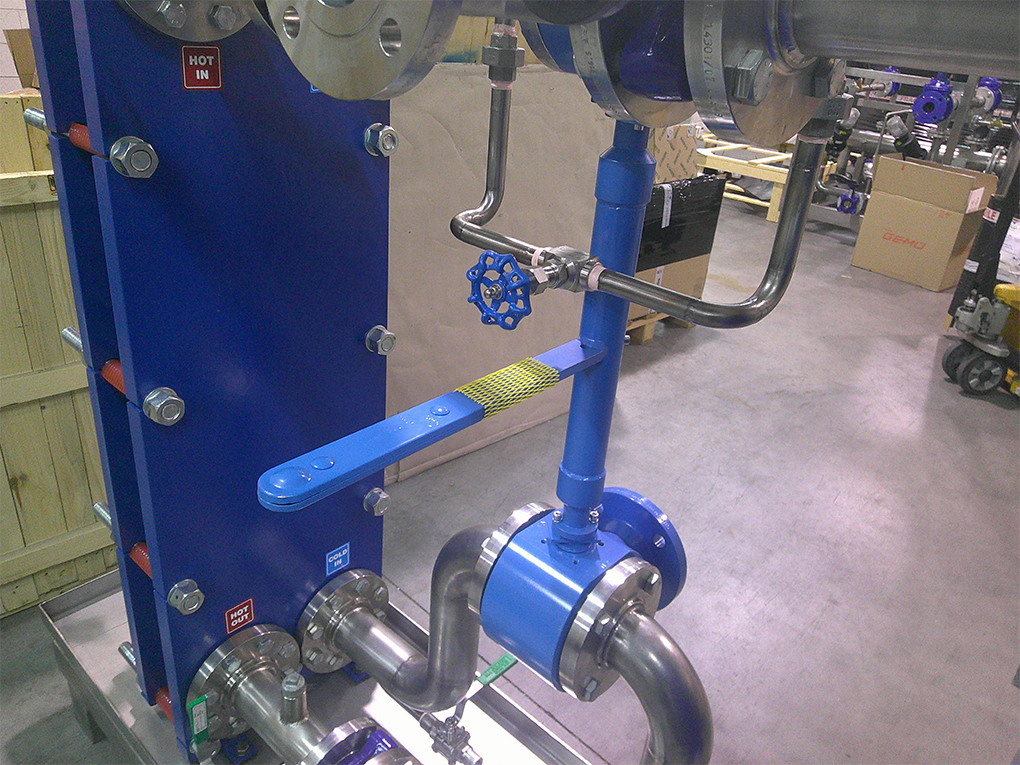

A new video on our Tempco Youtube Channel, dedicated to cleaning operations of brazed plate heat exchangers, closes the roundup on the services for cleaning of heat exchangers. Let’s start saying that brazed plate exchangers are the one that are less cleanable among all plate heat exchangers. That’s because these are realized as a unique compact block totally welded and furthermore they are usually employed with clean fluids.

This is because internal channels are very tiny and small, we’re speaking about hydraulic passages with a diameter of 2 – 2,5 mm. Clearly, a mechanical cleaning is impossible to achieve. A chemical washing is possible, the classic CIP, Cleaning in place, using washing cleansers more or less aggressive that can remove scaling, deposits of dirt or grease that have been collected inside the exchanger.

Obviously, the exchanger must allow at least a fair passage for the fluid, meaning that if the brazed plate exchanger is completely clogged, it is no more possible to clean it. That’s because the fluid won’t be flowing inside the exchanger, or anyway it will create preferred flowing channels but it won’t clean the overall plates pack.

Therefore, it is better to employ brazed plate exchangers only with clean fluids. Or otherwise, make a careful check of pressure drops, and as soon as there is a sign of an increase in pressure drops, at constant flow rate, that is the warning that the brazed plate exchanger is starting to get dirty. It is then suitable to immediately make a cleaning intervention, in order to avoid a complete clogging of the exchanger.

Stay updated on the latest applications of thermal energy management by subscribing our monthly Tempco Newsletter – Solid Temperature.