Never tired to speak about fouling factor on thermal transfer surfaces in heat exchangers, as we’ve already did in the past. This is indeed a crucial aspect in the design and engineering of every cooling and heating system that employs heat exchangers, and it can be defined as the theoretical resistance to heat transfer due to the deposition of layers of dirt and substances upon thermal transfer surfaces. In order to correctly evaluate the fouling factor it is essential to determine the kind of application, the temperatures involved within the process and, of course, the kind of fluids that are supposed to flow inside the exchanger.

There are four types of fouling mechanisms, that can be classified as chemical, biological, caused by deposition and related to corrosion events.

Chemical fouling

This category includes the fouling caused by the deposition of substances generated by chemical reactions that are trigger in fluids when certain temperatures are reached. An example is the formation of salts and carbonates that precipitate at the temperature of approx. 55° C. Or also, in the dairy industry, milk protein got burned at certain temperatures, settling a film upon the thermal transfer surfaces.

Biological fouling

Micro organisms can grow within the fluid, such as algae, fungi and bacteria, that stick on thermal transfer surfaces lowering the transfer efficiency, and also fostering corrosion. The selection of the right materials of the plates, which inhibit the growth of these micro organisms, is here a feasible solution.

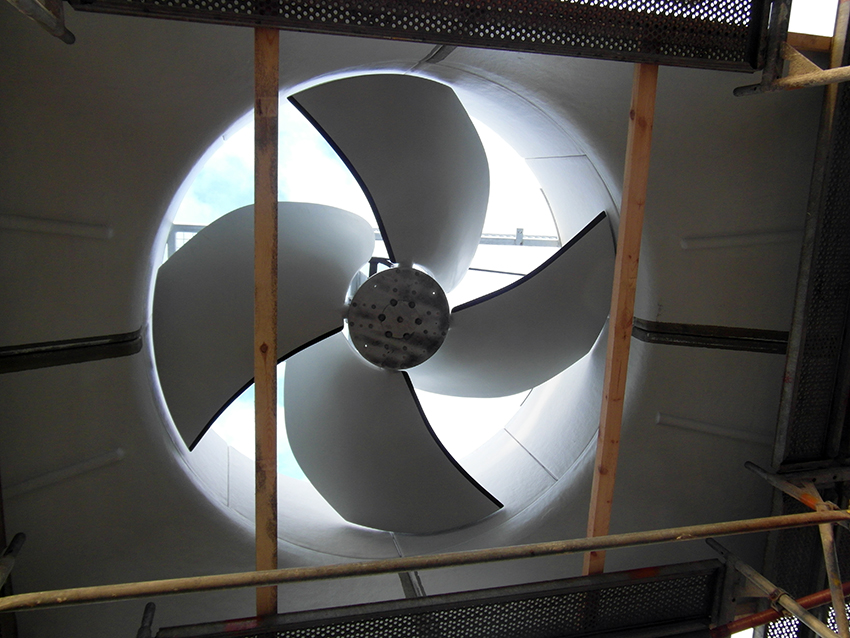

Deposition fouling

Cooling and heating tasks in production processes often involve the presence of process fluids containing suspended particles. It is thus necessary to adopt some design precautions, such as the right section path of the flowing channels, the vertical mounting of the exchanger (so that gravity helps draining the particles toward the bottom) or to guarantee a suitable speed flow rate. Otherwise, these particles can settle and grow on thermal transfer surfaces, compromising the thermal efficiency.

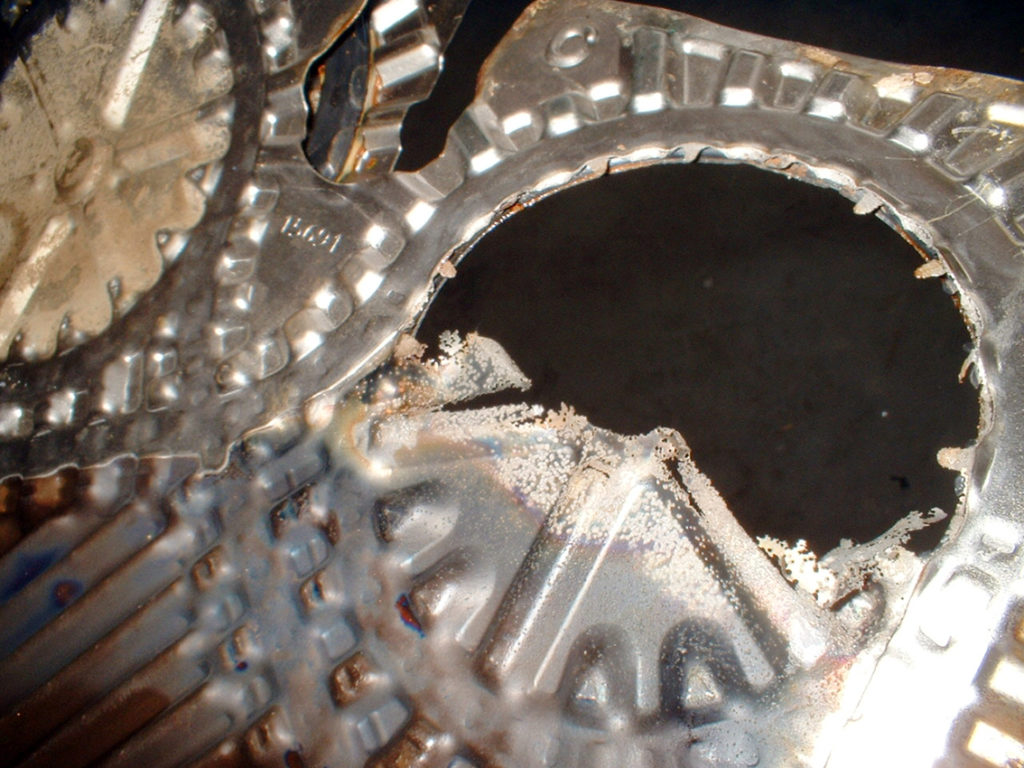

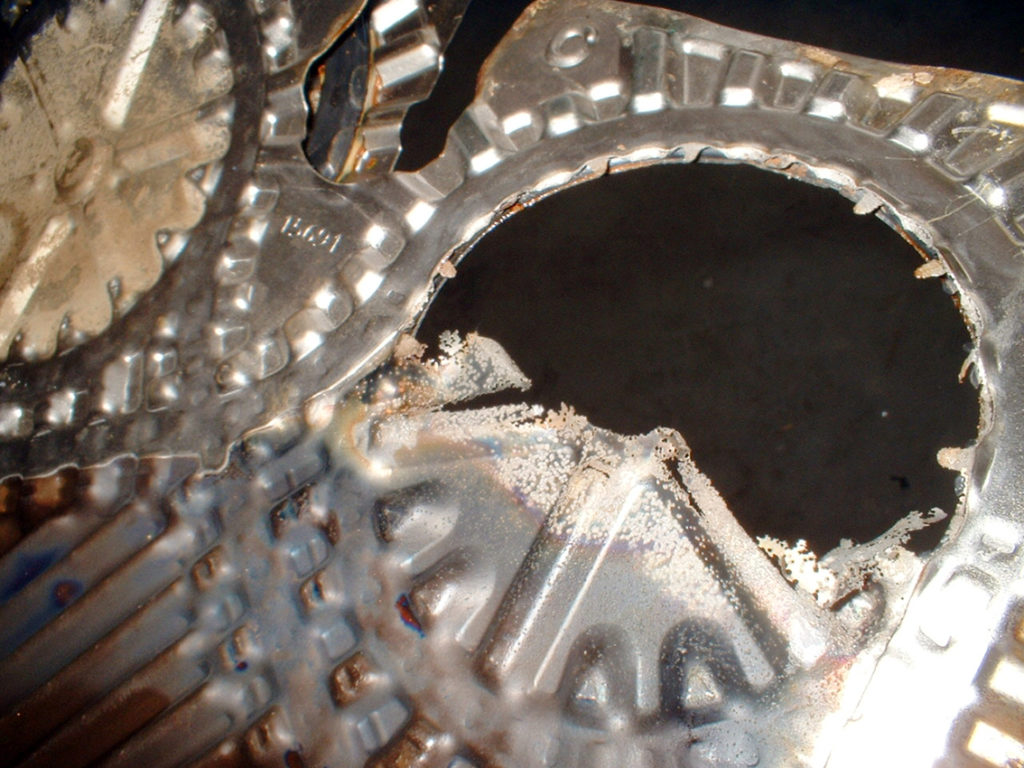

Corrosion fouling

A wrong selection of plates’ materials can lead in the long term to severe corrosion effects, with the formation and deposition of oxide layers on thermal transfer surfaces, causing an isolation action that lowers the heat transfer.

In many cases, cleaning activities through chemicals or also mechanical brushing can be a solution, removing scaling and layers of dirt that in the long term can lead to the complete clogging of the exchangers, and all the way to damaging and breaking the plates.

But it is also possible – and of course preferrable – to prevent fouling in heat exchangers, thanks to:

- Proper selection of the type of exchanger based on the application

- Correct selection of the exchanger’s design and materials of the plates

- Softening and filtration of fluids, improving their chemical/physical conditions

- Study of special corrugation of the plates to ensure a suitable turbulence of the fluids

Finally, an interesting innovation comes from nanocoating, with the development of nanotechnology applied to HVAC and refrigeration. These are nano-tech solutions studied at the Saarbrücken Leibniz Institute for new materials, for instance, offering antimicrobial, anticorrosion and anti adhesion properties, avoiding the deposition of dirt on treated thermal transfer surfaces, therefore reducing the costs and efforts related to periodical cleaning and maintenance operations of heat exchangers.

Subscribe here to our Tempco Newsletter – Solid Temperature.