We gladly host a contribution of Houston-based TRG Datacenters, a company that offers an innovative and customer-centric approach to datacenter management, here giving some very clear and useful tips on how to make an effective IT disaster recovery plan work.

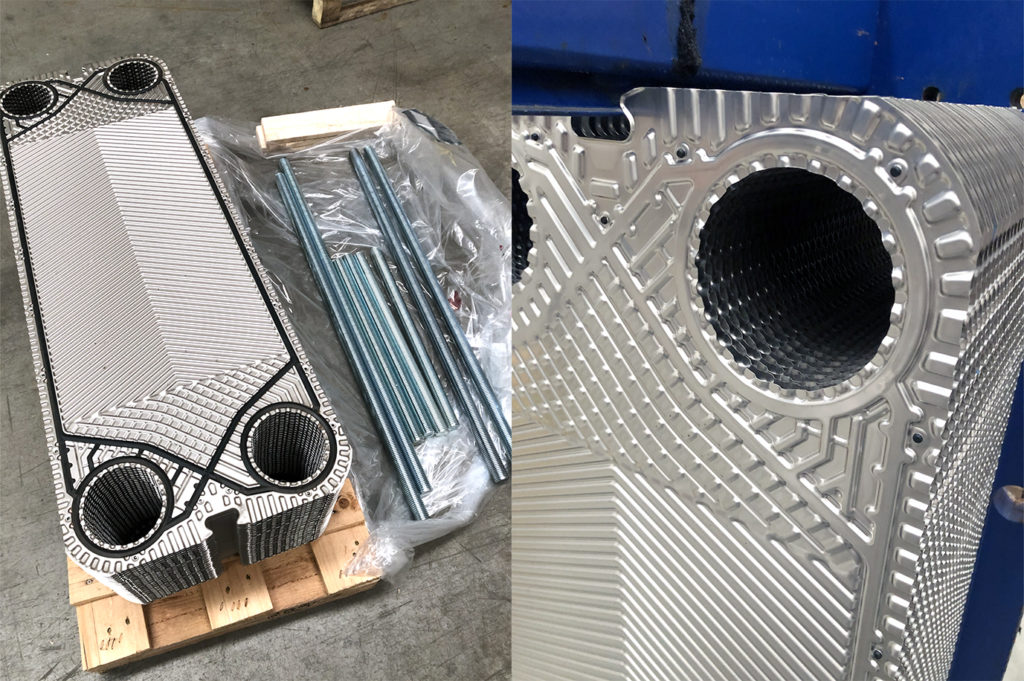

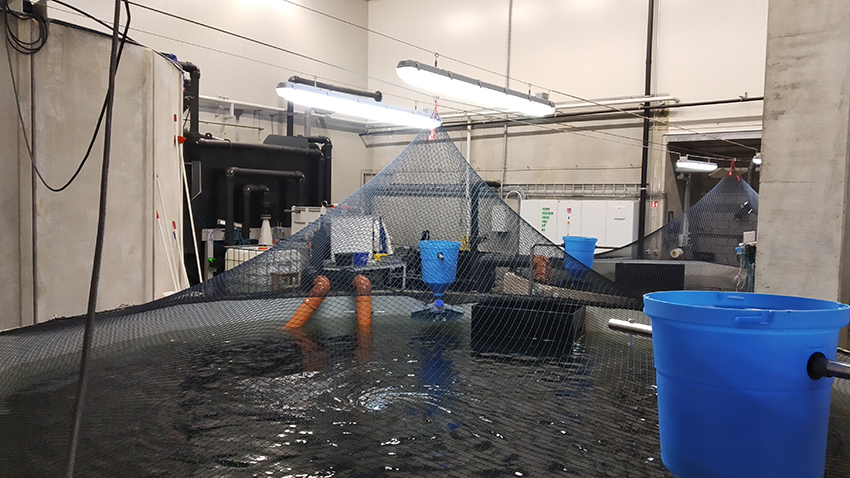

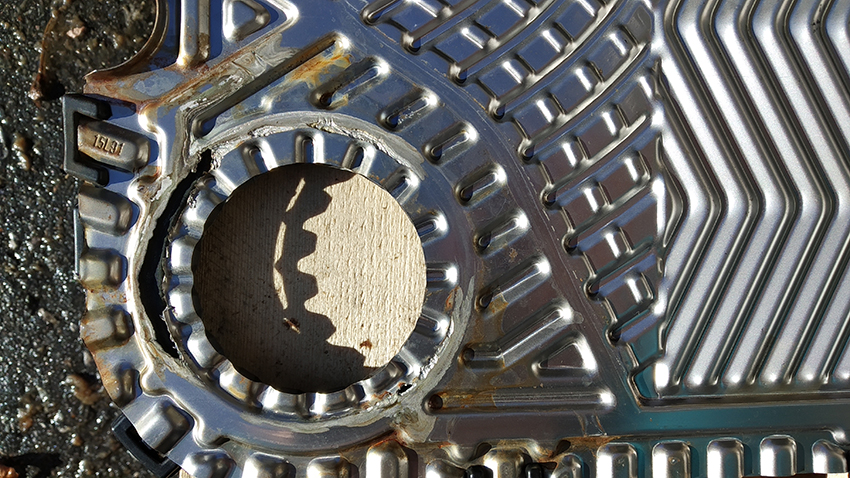

Data centers are an important application field for Tempco, especially with TCOIL immersion heat exchangers for liquid cooling, also a crucial asset to ensure the business continuity of IT infrastructures.

An effective IT disaster recovery plan is vital for all businesses. When it comes to IT disasters, slow responses and mismanagement can quickly prove catastrophic. Data can be lost, reputations can be damaged and customers can be left very unhappy indeed. But an effective disaster recovery plan can help businesses to limit the impact of all manner of problems, guiding teams through the murky waters and straight out the other side.

Take a look at some of our top tips to ensure that your business’s IT disaster recovery plan is as good as it can be, and make sure your company is fully protected.

Regular testing and clear processes

Too many companies have a clearly defined disaster recovery plan that they hardly ever test. And when you consider some of the costs involved in full testing processes, it’s easy to see why. But testing is vital in ensuring the effectiveness of any disaster recovery plan.

Plans should be tested regularly, and in full. Because let’s face it – it’s quite likely that every single aspect of your recovery plan won’t go exactly as you had imagined. Thorough testing will enable you to iron out any little hiccoughs at your own pace, and double check every detail of your plan. Do this and you’ll avoid potentially stressful, time-critical challenges if you ever do need to employ the plan in a real-life situation.

Awareness of the human factor

It’s a slightly awkward fact that a whopping 70% of IT outages aren’t actually caused by problems in infrastructure design. They’re the result of human error.

Errors can be caused by many different factors, ranging from insufficient training to poor management decisions. There’s no failsafe way to protect your systems from human error, but there are ways to minimise the risks.

We always recommend that the vast majority (at least 70%) of your disaster recovery planning efforts focus on the humans that power your business. Invest time and energy in the human aspect of your strategies, and you’ll start to limit the associated risks.

A well defined set of objectives

Before you can create the ideal disaster recovery plan, you need to know what constitutes a disaster in the eyes of your business. Decide on what a disaster, and subsequent recovery would really mean, and how you might measure the success of your plan.

As a starting point, consider the amount of uptime your business requires, what you mean when you say that systems are ‘working’, and what your teams would call a success in terms of disaster recovery.

A role in day to day management of operating responsibilities

Disaster recovery planning should never be a task that’s done once and quickly forgotten about. For plans to be truly effective, they must be discussed and updated regularly.

It’s a good idea to incorporate disaster recovery into the day to day management of operating responsibilities, and make sure all team members are on board with what the plan entails, and how to use it. Disaster recovery strategies must become part of normal operations for IT teams, if they are ever to fulfil their real potential.

Few things are as important as disaster recovery planning, particularly when you consider the impact that inadequate plans and processes can have on a company. Take the time to make sure your systems are protected from the wide range of risks out there. Think carefully about what disaster planning means to your business, and you’ll be able to effectively prevent the hugely damaging impact of insufficient planning.