Here’s a new video rolling out a series of videos dedicated to the mechanical sector, and this new one in particular is about plate heat exchangers in hydraulics applications.

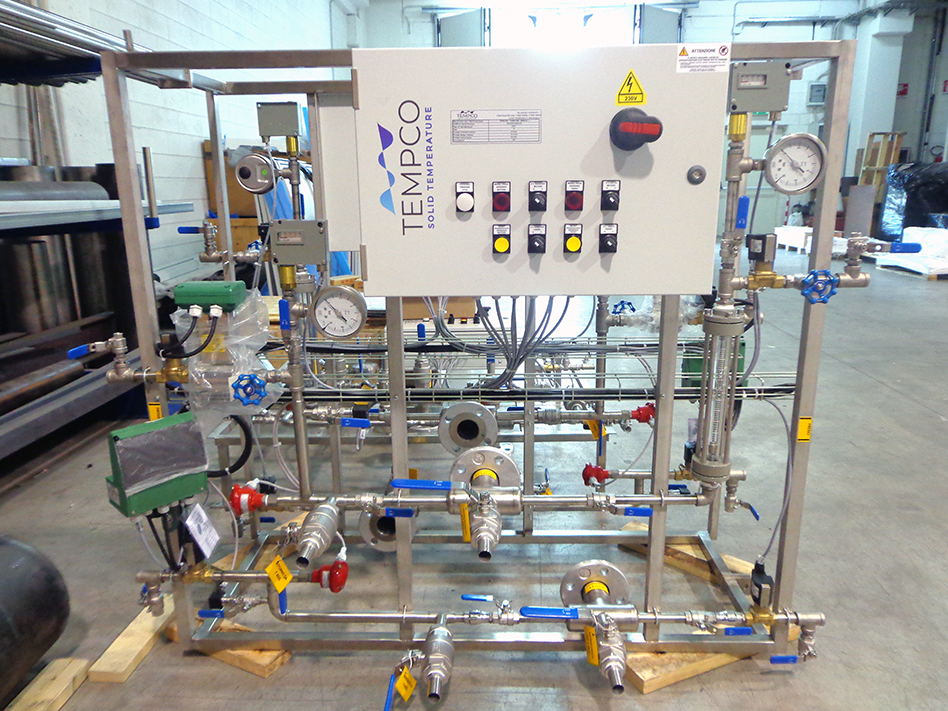

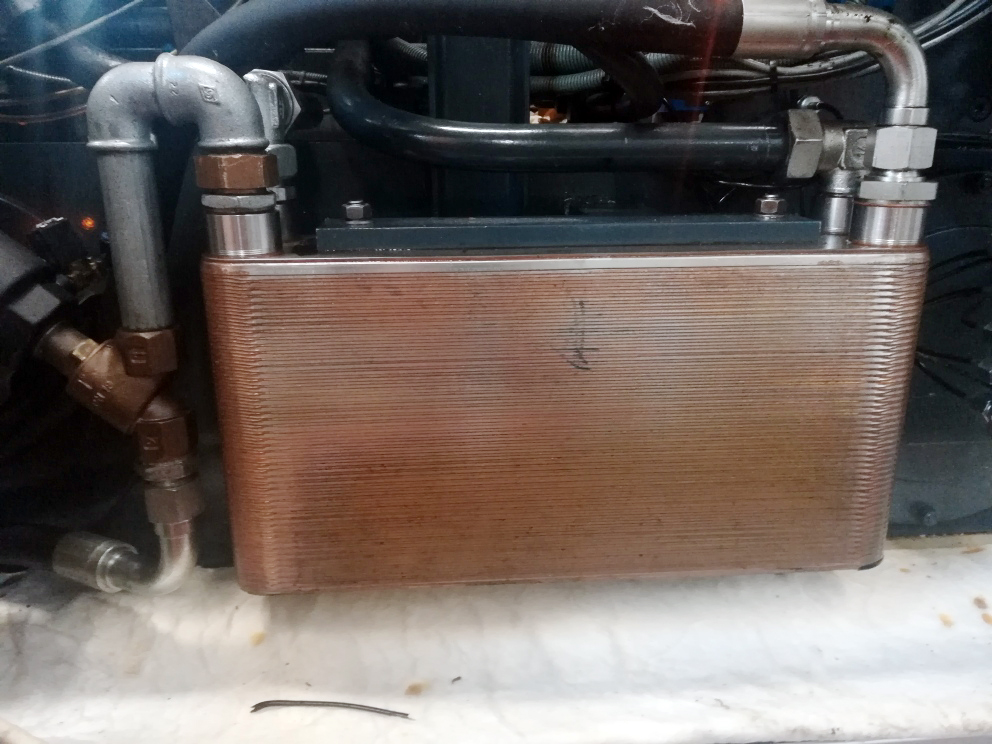

On hydraulics plants, until a few years ago, shell and plate exchangers were commonly employed, or also air cooled exchangers. While there is not very much to say about air cooled exchangers – in fact radiators using electric fans -, an interesting evolution happened on the side of the water cooled process: for hydraulic oil cooling, here shell and plate exchangers were, and still are, a widely employed solution.

But recently, plate heat exchangers became more and more employed for hydraulic oil cooling applications, both brazed plate and inspectable exchangers. The main advantage they offer is the fact that they allow cross temperature, on the contrary of what shell and plate exchangers can do. In hydraulics plants, the oil have to bee cooled at a relatively high temperature, because the hydraulic oil must keep an average temperature of about 40° C, being cooled when it comes back from hydraulic drives.

Therefore, there is no need of a very hard cooling, and thus a plate heat exchanger is a profitable solution because it allows to employ cooling water at higher temperatures. Indeed, there is no need of water at 15-20° C, since it’s possible to have evaporative tower water at the temperature of 30° C available in order to achieve the same cooling task. This is possible thanks to the higher thermal transfer efficiency, and also the possibility to use a lower thermal transfer surface.

In addition, as they permit to cross temperatures, plate heat exchangers allow to use a lower amount of cooling water. Being it an ideal solution wherever there is a lack of cooling water within the facility, allowing to take maximum advantage of the limited cooling water available obtaining anyway a very efficient cooling of the hydraulic oil.

Subscribe here to our monthly Tempco Newsletter – Solid Temperature.