Among the measures to contrast climate change in industry, there is certainly the increasing transition to equipment that uses environmentally friendly refrigerants, with the aim of reducing greenhouse gas emissions. However, the use of environmentally friendly refrigerants, such as R290, is subject to strict regulations, and the filling quantity of the equipment must be carefully monitored. This is a very important topic, as highlighted in a recent article published by Kaori, our technological partner for plate heat exchangers.

The need to carefully calculate the quantity of natural refrigerant poses a great challenge in product design, making the calculation of the volume of the heat exchanger even more crucial.

In particular, the article highlights how the performance of a heat pump is related to several factors such as the heat transfer area (HTA), the heat transfer coefficient (U) and the logarithmic mean delta T (LMTD) of the heat exchanger. However, the system sizing rule is even more complex, as it also includes other factors such as refrigerant charge, expansion valve superheat adjustment, refrigerant side volume and heat exchanger pressure drop, and it is impossible to consider just one parameter.

When considering the replacement of a brazed plate heat exchanger of another brand with a Kaori exchanger, it is therefore necessary to consider the following:

1. The declared catalogue value and the actual volume value of the product of other brands may differ, therefore it is recommended to use it only as a reference. Also, if a refrigerant distributor is installed in the heat exchanger, this may affect the effective volume value. Therefore, the exact volume can be measured after filling it with water.

2. The volume of the heat exchanger should not be the main parameter driving the replacement; the corresponding relevant system parameters should instead be considered.

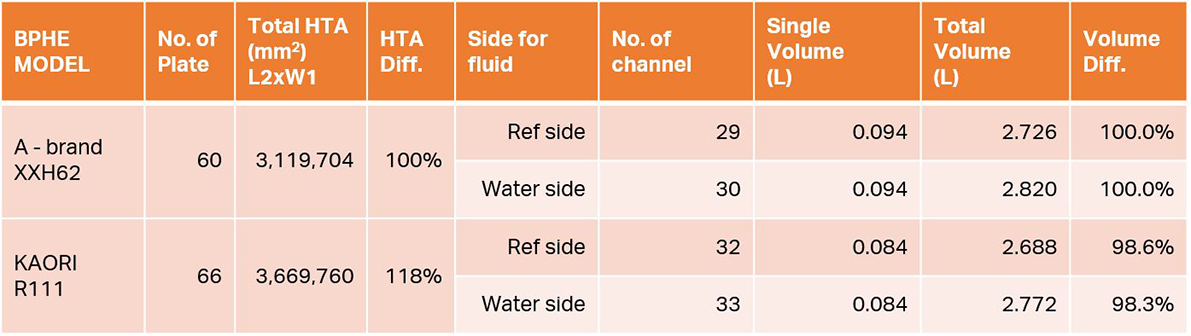

A practical example can be of help in this regard: a brand XXH62-60 (refrigerant side volume approximately 2.73 L) corresponds to the same volume of a Kaori R111 brazed plate heat exchanger (BPHE), which requires 66 plates, with a consequent total number of plates and total excess heat exchange area (+18%). Furthermore, the refrigerant flow rate decreases, the saturated evaporation temperature increases due to the pressure drop, and if the expansion valve and refrigerant volume do not match, this can adversely affect the final performance.