Plate heat exchangers are quite simple equipments with a very consolidated technology for thermal transfer in industrial processes. The kind of application can anyway require very special adjustments and engineering attentions that can turn a common plate heat exchanger into something very special. A typical example is the oil&gas industry, which entails a very much more accurate design of a plate heat exchanger, with a series of special engineering features:

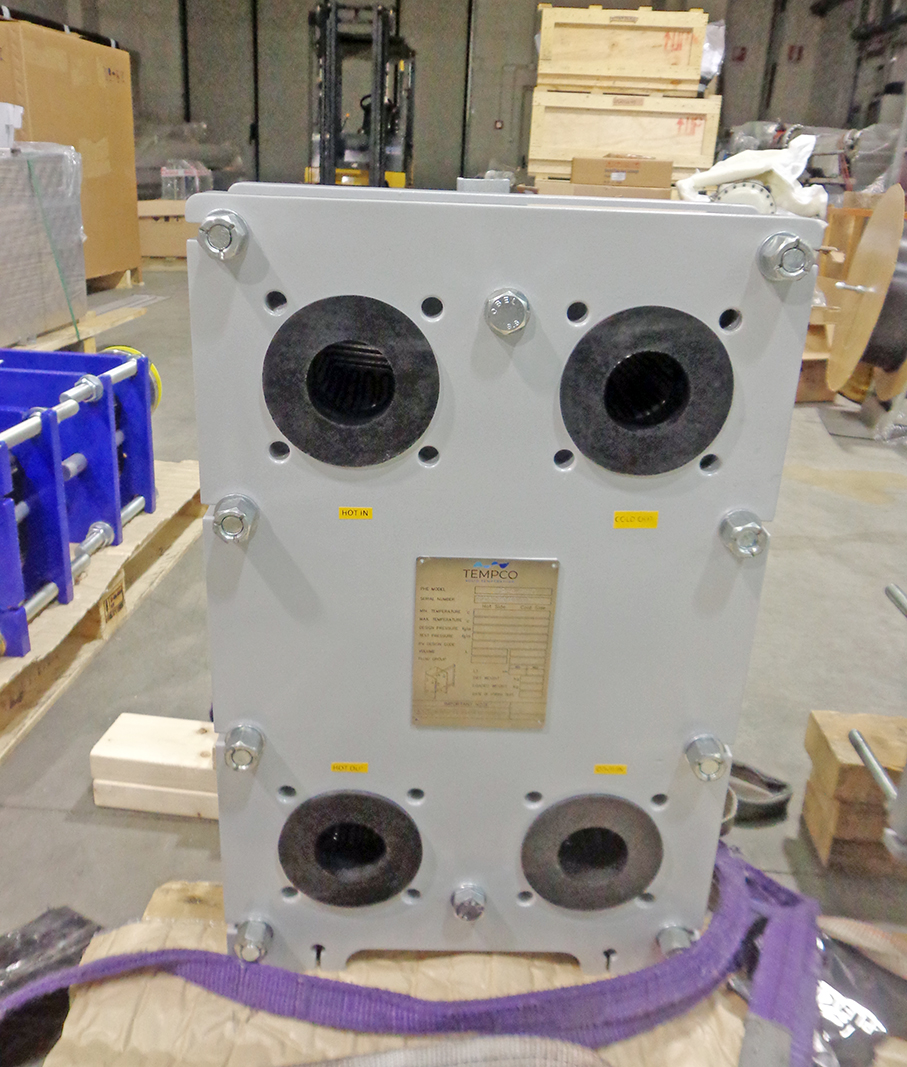

- Anti-corrosion coating cycles (such as for C5 M environments)

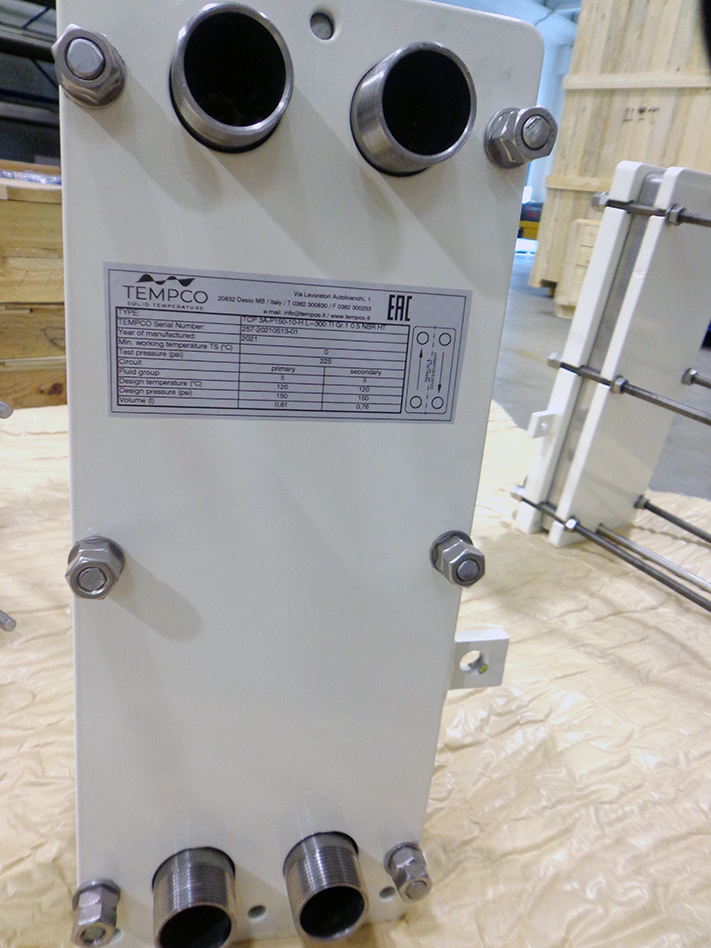

- Stainless steel nameplates and data plates

- Line connections made in AISI 316

- Thermal security coefficients increased (suitable fouling factor rate)

- Earthing systems

- Declaration of conformity for ATEX area installation

- Certifications of materials

These features are referred to the construction and selection of constructive materials of the plate heat exchanger, but also to all the engineering evaluations and the technical documentation required to ensure the exchanger is suitable to cope with the challenging conditions of the harsh industrial environment.

Stay updated on the latest applications by subscribing our monthly Tempco Newsletter – Solid Temperature.