In Tempco we are currently working on two new projects for temperature regulation for an important manufacturer of plants aimed to process food and pharmaceutical products. A first part of the plant is dedicated to the cooling of stainless steel conveyor belts that provide the transportation and lamination of the products, forwarding them to the final flaking process.

The other part of the project is dedicated to heating the product. The product gets spread out along the conveyor belt in order to obtain flakes or tablets from the layer, at the end of the cooling step explained above here.

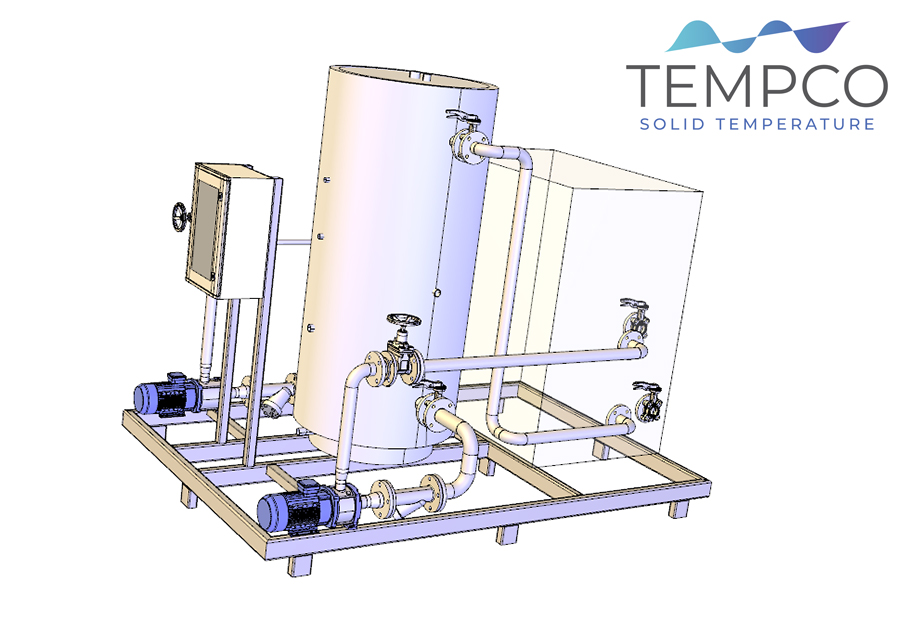

As often required by food and pharma applications, these are also highly personalized plants that require a previous accurate study of the piping, enabling the integration in the existing machinery at customer’s facility. In addition, there is also the study of the flow and the thermal and hydraulic requirements of the production process. Overall, the plant is constructed in stainless steel, enhancing our basic standard machines with a customized execution to meet the installation needs of the customer.

The typical configuration includes a chiller condensed with water or air, for the production of refrigerated water serving multiple utilities:

- Process heat exchanger

- Air treatment unit

- Spraying nozzles

- A diathermic oil thermoregulating unit

The thermoregulation unit ensures to keep at constant temperature levels equipments such as:

- Pipings for product distribution

- Conveyor belts distribution system

- Heating process’ components

Subscribe here to our Tempco Newsletter – Solid Temperature.