The treatment of precious metals is a very interesting and challenging field for thermoregulation applications. Recently, we’ve supplied a couple of thermoregulating units expressly developed for a customer specialized in the recovery and refining of precious metals. These last two thermoregulating units supplied joined the approx. 12 machines installed at the customer’s facility through the years, working on reactors employed in the refining process of precious metals.

The two new thermoregulating units are the result of the longtime experience of the previous installments and of the co-engineering with the customer, that requires in its production process very extreme and reliable equipments, ensuring continuous operations with pressurized water at the constant temperature of 135° C.

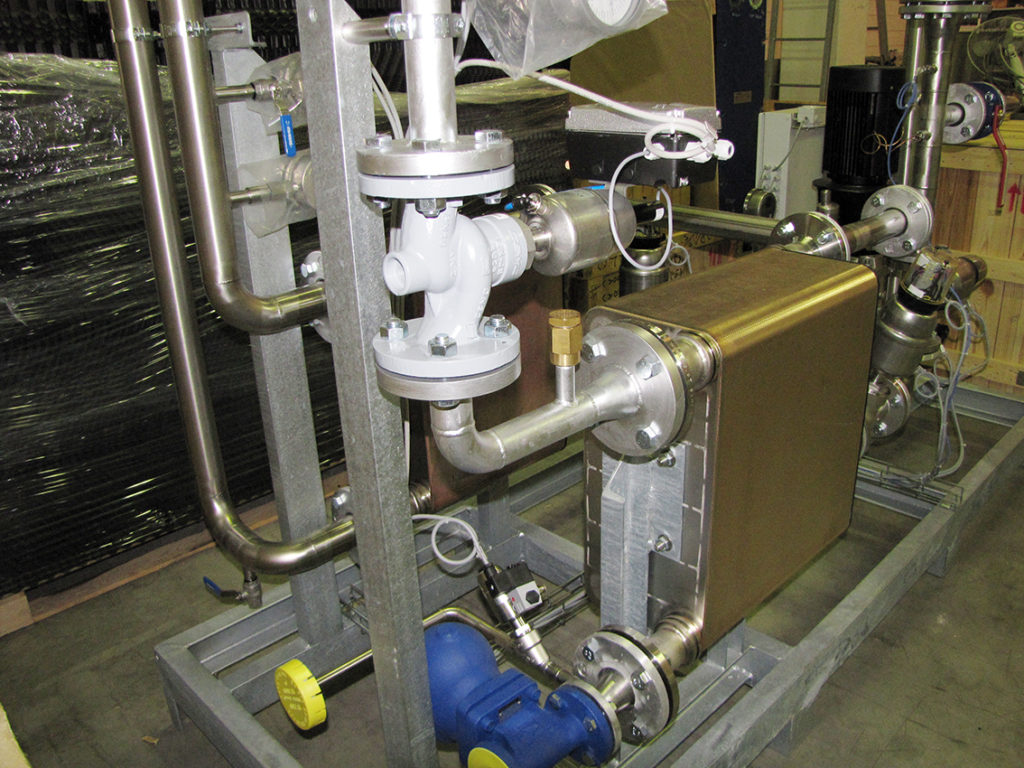

This peculiar need required the implementation of specific components, such as a Grundfos pump with special liquid-cooled seal. The thermoregulating units work with brazed plate heat exchangers in impact version for high pulsating pressures, specifically engineered for employ with steam and pressurized water. Modulating control valves and on/off pneumatic valves have also been installed, equipped with metallic actuators in order to stand extreme thermal stresses.

This peculiar need required the implementation of specific components, such as a Grundfos pump with special liquid-cooled seal. The thermoregulating units work with brazed plate heat exchangers in impact version for high pulsating pressures, specifically engineered for employ with steam and pressurized water. Modulating control valves and on/off pneumatic valves have also been installed, equipped with metallic actuators in order to stand extreme thermal stresses.

The units finally have a flowmeter monitoring the flow rate, a crucial factor to ensure the thermal exchange efficiency in the reactors. Pipings are all made of stainless steel, with flanged connections (and welded wherever they’re not flanged) and spyrometallic gaskets resistant to high temperatures.