The most recent developments in refrigeration and chilling solutions are aware of energy efficiency issues: chiller manufacturers have recently developed cooling units consisting in free cooler enhanced chillers, also having inverters on higher efficient modules allowing the cooling system to adjust rotating speed and power supply on compressors.

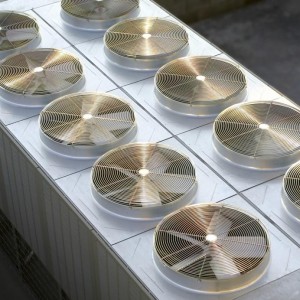

This is an innovative and green-oriented solution that Tempco offers for integration in its industrial cooling plants and solutions, consisting in chillers matching two functions in a unique unit: a traditional chiller combined with free cooling capacity, using two separate arrays of fans respectively dedicated to the chiller and free cooler sections.

With favorable climatic and temperature’s conditions, the free cooler automatically replace the energy consuming chiller, ensuring the same performance levels in thermoregulation, but drastically lowering electric energy consumptions, allowing great costs savings and benefits in energy efficiency.

Unique inlet and output of water circuit, and a unique power supply connection, make this technology even easier to install.

This kind of chiller/free cooler integrated thermal machines are also available on the market with double compressors and inverter, regulating the rotating speed in one of the two compressors: the speed adaptable compressor in the chiller adjusts consumes to the effective needs, matching it with the free cooler contribution to the cooling duty, allowing a constant cooling power regulation in a range between 15% and 100% of nominal power installed, always ensuring maximum performance levels in temperature’s control. The inverter enhanced solution further increases energy saving, for extreme energy efficiency on the chiller.

The higher energy saving chillers also include:

– electronic thermostatic valves

– brushless motors driven fans, both in free cooler and chiller circuits

These components provide a further cut-down in energy consumes, due to a better performance of 2-3% of the thermostatic valve, while brushless motors in fans can ensure, in cold winter season, up to 90% of energy saving in the total amount of power installation.