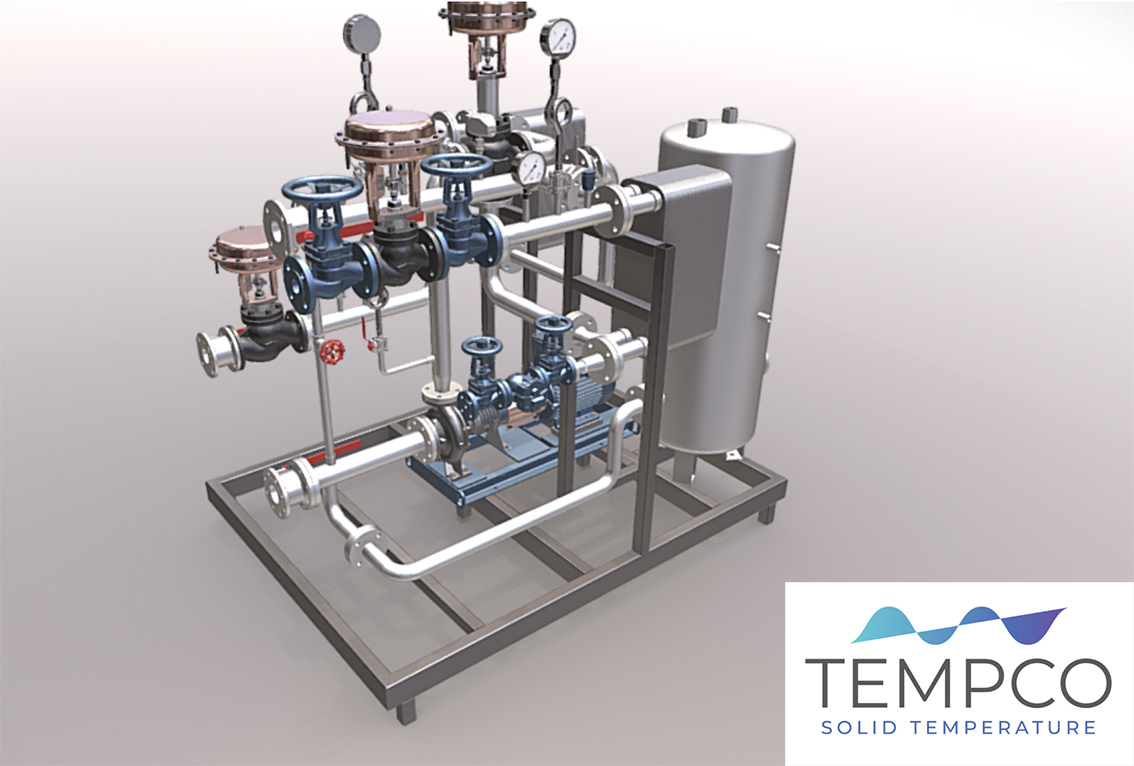

We’ve realized a series of videos showing the schematic working layout and the fluids flow in some of our Tempco thermal machines. This first one here shows in particular the actual functioning of a Tempco TREG HCST monofluid thermoregulating unit, with steam heating circuit.

Monofluid thermoregulation units have been the topic of a series of articles and videos in our Tempco Blog. This kind of solution, often employed for temperature regulation of reactors in chemical and pharmaceutical processes, offers the advantage of working with a unique working fluid, which is regulated at the specific temperature required at any different step of the production process. Cutting times required to empty the jackets of the reactors and to fill the plant with different working fluids.

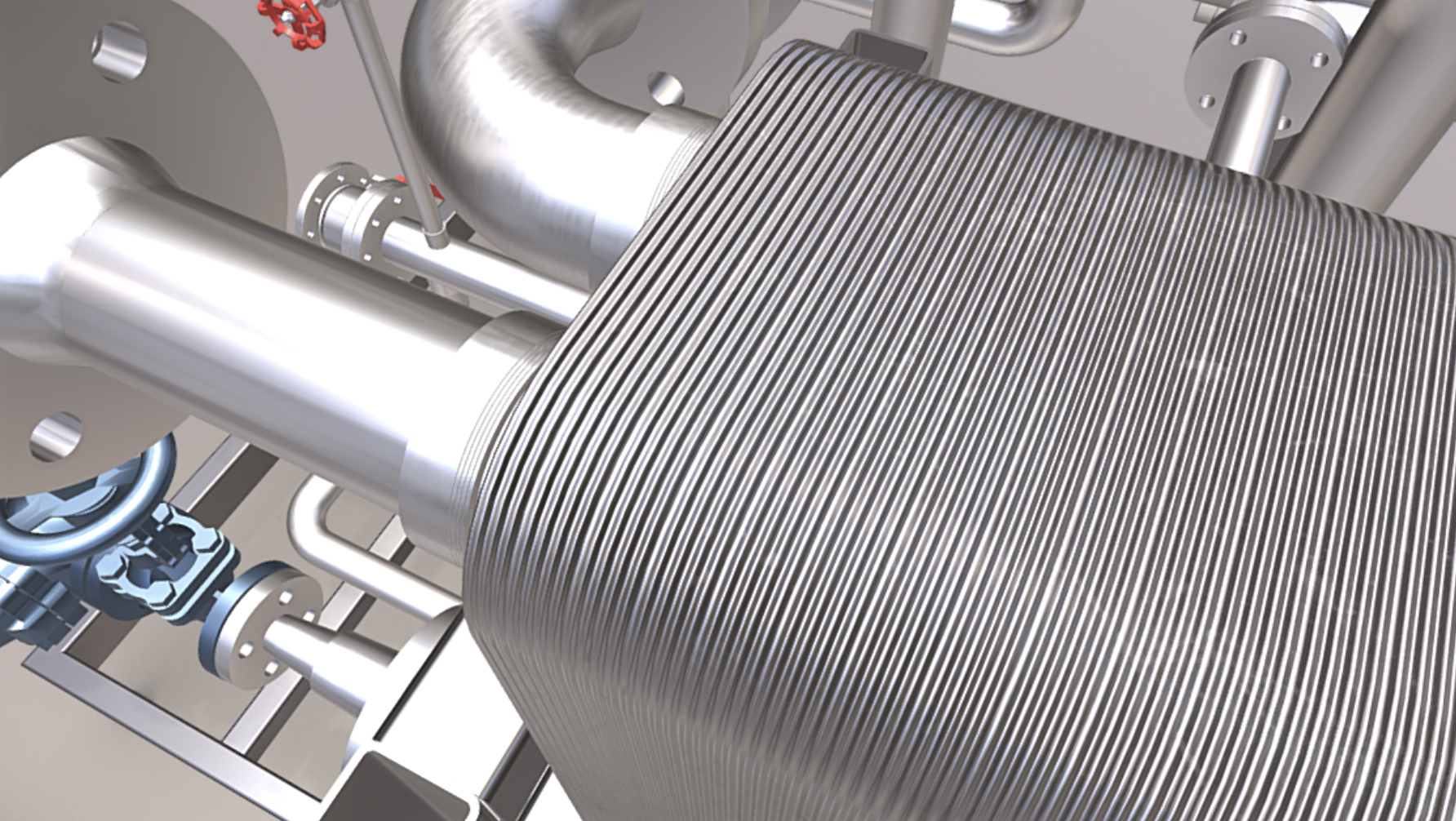

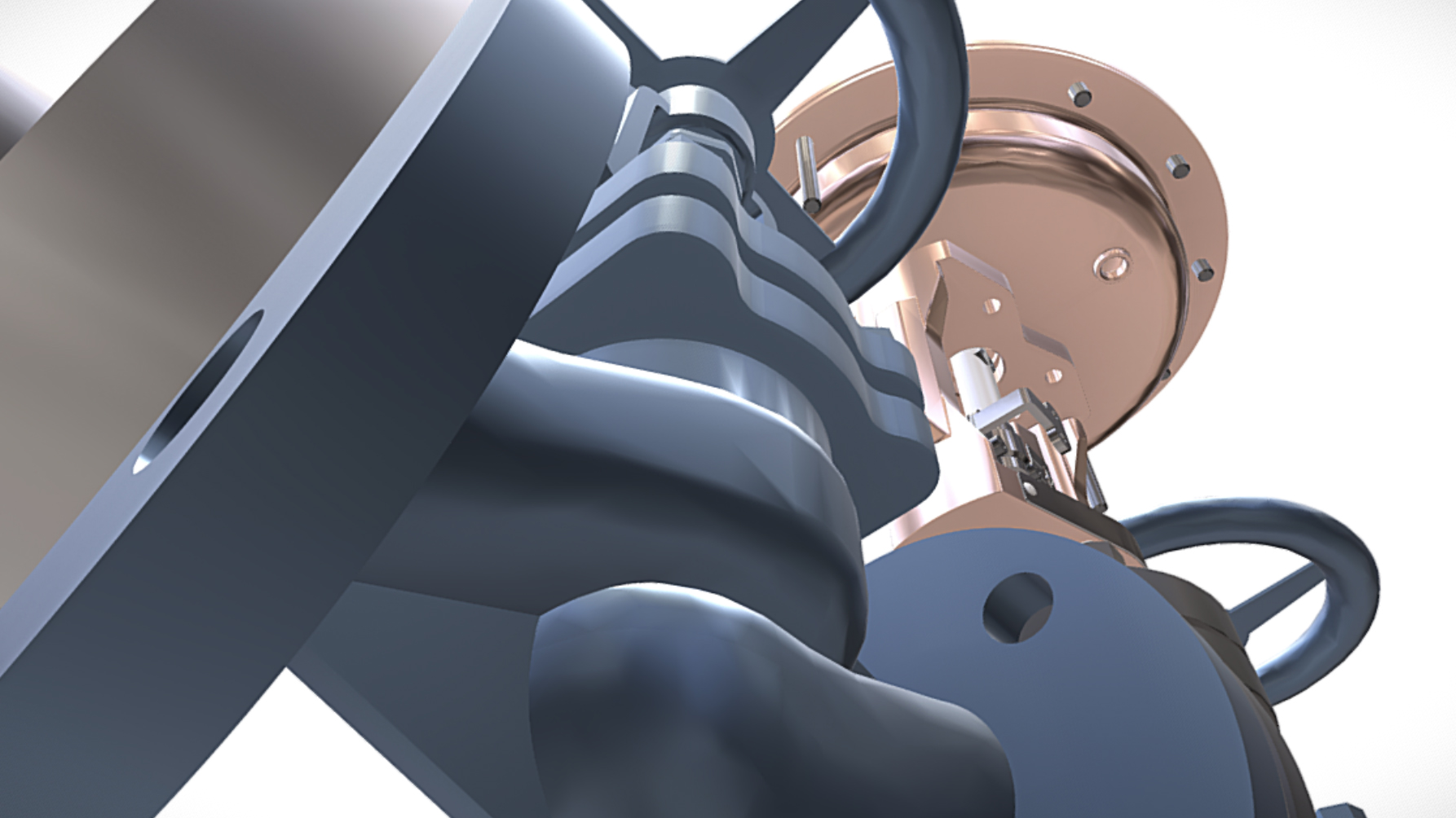

The video shows the circuit for water inlet, cold when entering the unit, which gets heated using a plate heat exchanger with steam as heating fluid. The circuit dedicated to the discharge of the condensation eliminates water produced by the cooling of the steam during the thermal transfer process. Water heated at the required temperature therefore goes out of the thermoregulating unit to be employed within the production process. Electronic control through PID thermoregulators allows precisions of temperature regulation of ± 0,5° C, ensuring a very fine and precise regulation of defined temperature cycles required for the production of pharmaceuticals, APIs and chemicals.

For some models of Tempco thermoregulating units, interactive 3D models are available in dedicated pages of the Tempco website, as for TCPU HC units pictured below here. Graphic animation allows to navigate and explore the machines, also zooming on details of the construction and engineering of these thermoregulating units. And so, have fun and enjoy the navigation!

Stay updated on the latest applications by subscribing our monthly Tempco Newsletter – Solid Temperature.