Commissioning completed last January of a very special thermoregulating unit, for implementation by the Italian Abete company within an innovative concept of a variable flow lubricating oil pump for the DEVILS Project, supported by EU Horizon2020 funds.

This is a very important project aimed to develop a new oil lubrication and heat management system in a VHBE (Very High Bypass Engine) Turbofan, realized by Rolls Royce for future aircraft applications offering high efficiency levels and reduced fuel consumption.

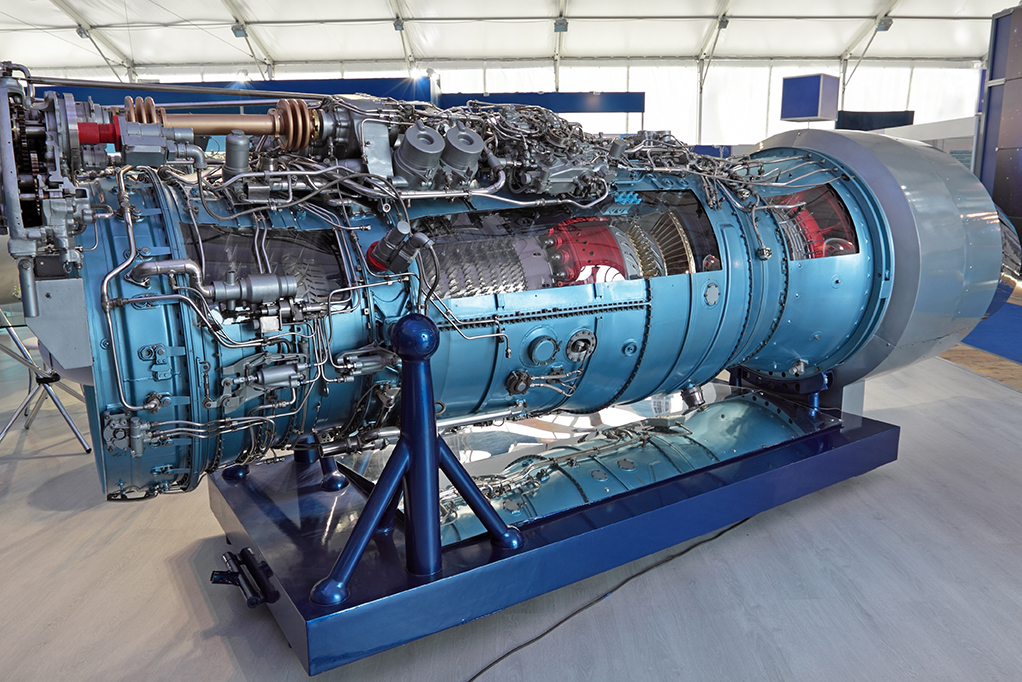

A Turbofan, or fanjet, is a special kind of air breathing jet engine that combines a gas turbine engine and a ducted fan employed in aircraft propulsion, which uses two separated air flows, a cold one and a hot one. Indeed, while in a turbojet all the air taken in passes through the combustion chamber of a turbine, in a turbofan some of the air bypasses it. The ratio of the mass-flow of air that bypasses the engine core divided by the mass-flow of air passing through it is called bypass ratio. A high bypass ratio thus entails lower consumes and reduced noise levels.

Model of gas turbine engine airplane in the section

The DEVILS (Development of VHBR Engines Innovative Lubrication System) project is then intended to develop an innovative oil lubrication system for Turbofans. This kind of engine presents indeed some challenging tasks to the oil lubrication and heat management systems, because the latest trends of developing aircraft engines that consumes less fuel involve higher speeds, loads and temperatures, due to the integration of high-power gearboxes (allowing high bypass ratio) and high-power starter-generators.

The diathermic oil thermoregulating unit we engineered in Tempco is integrated in the production line and stress testing of the special variable flow lubricating oil pump by Abete. This is a unit designed to work with diathermic oil at high temperatures, up to 300° C, with PID regulation of the temperature control and management through static relais. Likewise all of the similar applications we supply in this field, the unit is equipped with a magnetic drive pump and special components and fittings suitable for continuous operations at such challenging conditions.

The cooling section has a double purpose:

- Temperature retention for thermal drift compensation

- Final cooling at the end of the operations

The unit is equipped with a special heat exchanger able to withstand high thermal shocks.

Beyond Abete and Rolls Royce as end user, the DEVILS Project also sees the contribution of other important companies from the Campania Region: the leading Euro.Soft, which is to deploy all of the avionic controls, and Protom, in collaboration with the Engines Institute of the CNR of Naples and the Industrial engineering department of the Federico II University, as well as the Israeli company TAT. Objective of DEVILS project is as well to research, implement and validate smart fault detection and health monitoring algorithms to assist the system in reducing oil low flow rate needs and allowing advanced functions for predictive maintenance.

Subscribe here to our Tempco Newsletter – Solid Temperature.