The global Covid-19 health emergency requires a collective commitment that embraces all the companies directly involved in the production of individual protective devices and protective masks, respirators and medical equipment aimed to intensive care units, drugs and pharma products and all the services supporting the healthcare sector.

Many Italian enterprises are offering their support in this period, giving their innovation capacity and flexibility to help hospitals in severe difficulty due to the coronavirus outbreak.

Recent industrial reconversions and the readiness and creativity of entrepreneurs gave many great examples. Starting with Tenaris from Dalmine, near Bergamo, that supplied in record lead times a lot of tanks for the oxygen produced by Siad, but also the automotive world with Ferrari and FCA together with Magneti Marelli, ready to convert their production lines to increase the availability of ventilation machinery, supporting the activities of Siare Engineering, the leading Italian supplier of these essential medical equipments in intensive care units. The Armani Group has also announced that it will immediately start to produce medical protective disposable white coats for all the hospitals and the healthcare operators fighting the coronavirus from the front row.

Another brilliant example is the Isinnova Italian startup, that under urgency designed a special Venturi valve, printed in additive manufacturing, to connect respiratory masks to ventilators at the Chiari hospital, in Brescia. The same company then adapted a commercial snorkeling mask, by the sport gear and equipment specialist Decathlon, turning it into a respiratory mask for sub-intensive therapy, thanks to a special patented junction valve.

Tempco designs and realizes plants serving many industries that are often directly involved in the production of materials and products in the chemical, medical and pharmaceutical industry. The status of emergency put the production facilities under an intensive workload, so that equipment’s availability is becoming even more important and strategic when compared to usual market demand conditions. The best efficiency is also granted thanks so more frequent monitoring on all the industrial production processes, especially on heat exchangers, which are at the core of thermal energy control tasks.

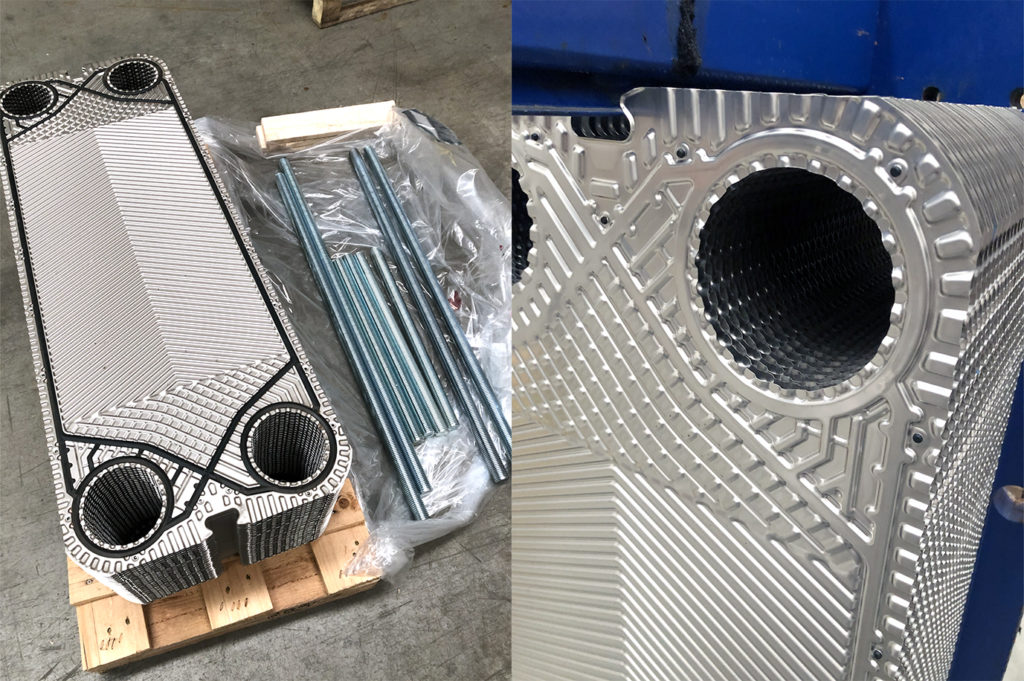

The images in this article are showing a plate heat exchanger with clear wear and corrosion signs, following years of working service, fouling on equipments and damaged gaskets. This is not a common heat exchanger: the plate heat exchanger pictured above is indeed installed in the facility of a customer in the pharma sector and employed in the production of an API, i. e. an active pharmaceutical ingredient, actually employed to treat Covid-19.

Last week the customer contacted us under extreme emergency, asking for our intervention for the substitution of the plate pack or the supply of a new equivalent heat exchanger, everything that was feasible but in the shorter time possible.

The customer is one of the many companies, part of the healthcare industry supply chain but not only, which are actually dedicating all of their resources and know-how to contrast the outbreak of the coronavirus disease in Italy.

Understanding the delicate emergency situation of our customer, that needed the exchanger fixed, ready and delivered as sooner as possible, a day of heavy work started in Tempco, after having retrieved all the necessary materials around Italy, with a considerable logistic effort.

On Friday morning the plate heat exchanger was finally ready for delivery.

We’ve been glad to be able to make our own tiny part too, and this clearly shows how everyone is deeply concerned in the solidarity chain triggered by the health crisis, and that economy is grounded on the tight collaboration among all the companies, big and small enterprises, and professionals.

To all the actors that during these times are making their best to contribute in this public health emergency, ensuring at the same time the best safety measures to all their workers, a huge applause and thanks, because working together all the industries can make a difference, as they’re already doing it.

Subscribe here to our Tempco Newsletter – Solid Temperature.