Thanks to the special health benefits offered by their waters, thermal baths are constantly on the rise.

In recent years, the development of spas and beauty farms has undoubtedly contributed to this favourable trend.

Thermal waters are used for many different therapeutic treatments and it is proved that they have been used for centuries:

- intake as a drink (mineral water drinking therapy)

- irrigation

- inhalation

- thermal or mineral baths (balneotherapy)

- ozone baths

- showers

- saunas

- mud baths

- underwater massages

these are some of the treatments involving the use of sulphurous waters.

In this field, adjusting the temperature of the various “thermal processes” plays a crucial role. Tempco has been operating in this specific sector for many years, with interventions such as system planning from scratch and the regeneration of existing systems.

Thermal water is an alkaline substance consisting of sulphur, iodine, chlorine, iron, calcium elements, and micro elements of other substances, and is classified according to a number of parameters:

- general characteristics: colour, odour, taste and clearness

- therapeutic properties

- chemical and physical properties

- chemical and physical qualities.

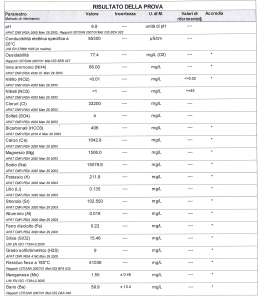

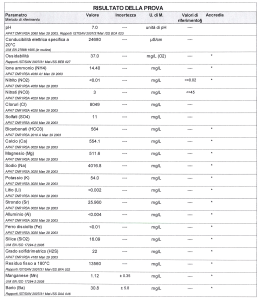

As we can see from a typical water analysis, thermal water also contains high concentrations of chlorides.

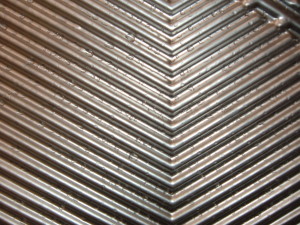

With such amounts of chloride concentrations, heat exchangers used in association with thermal water need to be manufactured with suitable materials. In the case of plate heat exchangers, heat exchange elements (plates) in titanium must necessarily be used.

Similarly, the connections will have to be made in materials that are equally resistant to corrosion:

- titanium

- PVC

- PVDF

or rubber coated.

We have implemented many upgrades on heat exchangers for existing systems, where, due to a wrong initial assessment, the customer had installed stainless steel plates. The installation of titanium plates has finally solved corrosion issues.