On our italian blog we often spoke about the flexibility of TCOIL heat exchangers.

I’m firmly believe in this product and every time we get feedback from market of this feature.

Few weeks ago our good customer operating in steel mill field, contact our technical department because a coil heat exchanger, internal to a waste water single effect evaporator is damaged; the coil has some pitting, but more important is totally scaled and externally clogged.

During the survey customer tell us, they have scaling problem once a month more or less…

The cleaning and maintenance is very expensive and ask many hours of hard work.

After a short meeting we give them the solution:

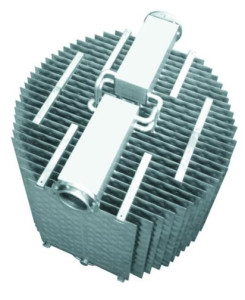

Tempco supplied a TCOIL plate pack for bigger and similar applications.

TCOIL give to customer many advantages:

- corrosion proof material

- low cost of supply

- easy cleaning

- lower scaling

- high thermal efficency

In a couple of week we make the new heat exchanger, suitable with actual tank. TCOIL flexibility give us the opportunity to make it fitted to existing plant.

Technicians install new TCOIL, make fren charge and restart the plant, which has improved capability due to high thermal efficiency of TCOIL construction.