In the pharmaceutical industry, precision cooling is essential to ensure the stability of chemical reactions and the quality of the finished product. Tempco recently supplied two water-cooled chillers, designed to operate with a water/glycol solution at -30°C, to cool reactors in a new pharmaceutical production line.

This supply, completed at the end of last year and completely commissioned in January with a positive on-site test, stood out for two key factors:

- Performance and reliability: system designed to ensure 24/7 operational continuity.

- Reduced delivery times: design, construction and testing completed on time, allowing the customer to start production without delays.

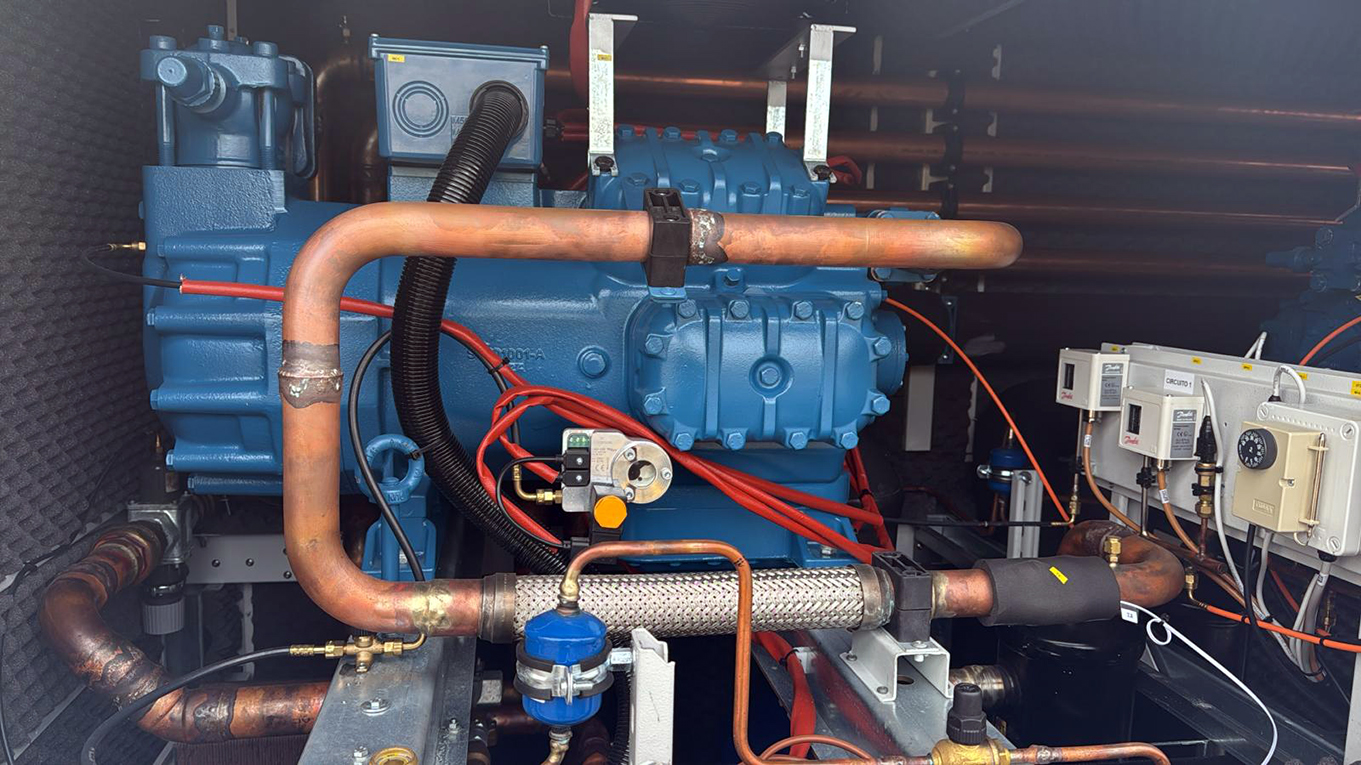

Below are the technical characteristics of the chillers supplied:

• Process fluid: 50% inhibited water/monoethylene glycol mixture

• Operating temperature: -30°C

• Cooling capacity: 75 kW per unit

• Water condensation with plate heat exchangers

• Indoor installation, in a safe area of the production site

• Power supply voltage: 400V – 3F – 50Hz

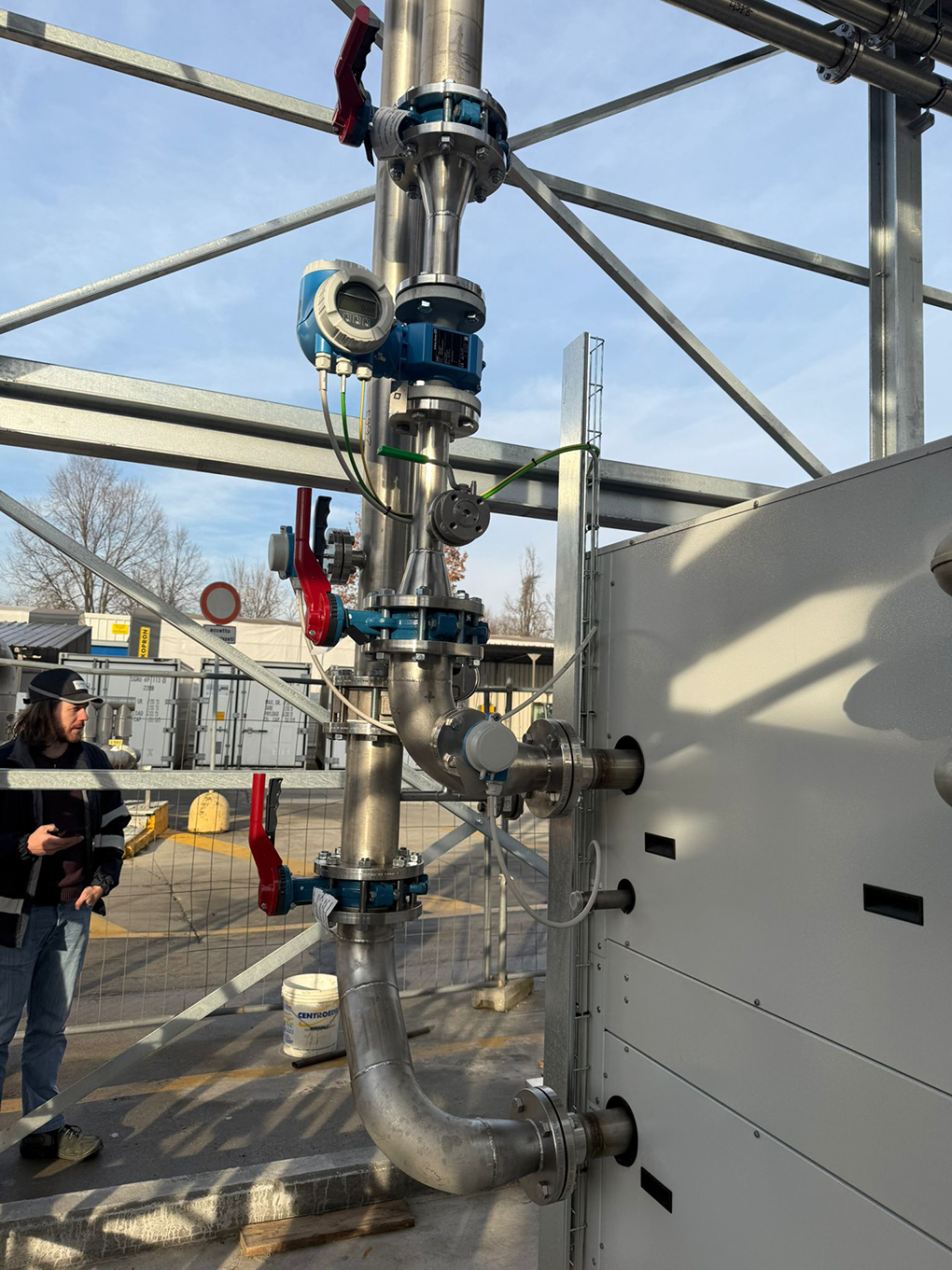

The chillers have an integrated hydraulic circuit, and each unit is supplied complete with: circulation pump, with a prevalence of 2÷2.5 bar, ensuring a stable and constant flow to the reactors; accumulation tank, to optimize thermal management and reduce temperature fluctuations; thermostatic valves, for precise control of the refrigeration regulation; AISI 304 stainless steel tanks and pipes, with stainless steel sheet insulation and cladding, to ensure durability and optimal thermal insulation.

Finally, there are several advantages ensured by this system created for the customer:

- Maximum energy efficiency – thanks to water condensation and the use of high-efficiency plate exchangers.

- Precision in temperature control – essential for the stability of pharmaceutical chemical processes.

- Operational reliability – designed to operate continuously without interruptions.

- Plug & play installation – thanks to the complete integration of the hydraulic part, the system was immediately put into production after testing.

This supply represents another example of how Tempco is able to develop advanced solutions for industrial cooling, with high efficiency and reduced delivery times. Thanks to our experience in the pharma sector, we were able to respond promptly to the customer’s needs, ensuring a high-performance and ready-to-use system.